Decommissioned Sites and Abandoned Wells

Millions of decommissioned and abandoned oil and gas wells, alongside thousands of miles / kilometers of decommissioned and abandoned pipelines need to be mapped. In the absence of reliable records, the task of identifying these assets remains challenging.

Key Challenges

Ensuring the safe retirement of decommissioned wells and pipelines is a challenge due to the lack of accurate geospatial inforamation and incomplete historical records. Other challenges include:

- Field Operator Safety Concerns: Wells in remote areas can pose safety hazards for operators due to difficult access.

- High Cost: Surveying extensive areas requires costly logistical planning and resources for field operations.

- Low Efficiency: Manual detection methods and tool limitations hinder effective identification of all targets in remote locations.

Swift Solution

Skipper NDT’s Argos sensor utilizes cutting-edge hardware and software for automated magnetic-based technology, ensuring precise identification of abandoned wells and pipelines.

- Remote Operation: Enables operations from a distance, enhancing safety and accessibility with minimal personnel required.

- Swift Coverage of Large Areas: Efficiently surveys extensive territories, optimizing operational timelines and resources.

- Real-Time Preliminary Processing: Provides immediate data analysis, facilitating quick decision-making during operations.

- Consistent Data Quality: Ensures reliability through standardized measurement protocols and calibration.

Site Feasibility

Assess locations for current conditions: right-of-way status, precise positioning, vegetation coverage, access points, and accessibility to a Cathodic Protection system (CP).

Automatic Drone-Based Inspection

Next, we mark inspection area boundaries and map above-ground markers for thorough coverage. Drones follow precise trajectories, capturing detailed data.

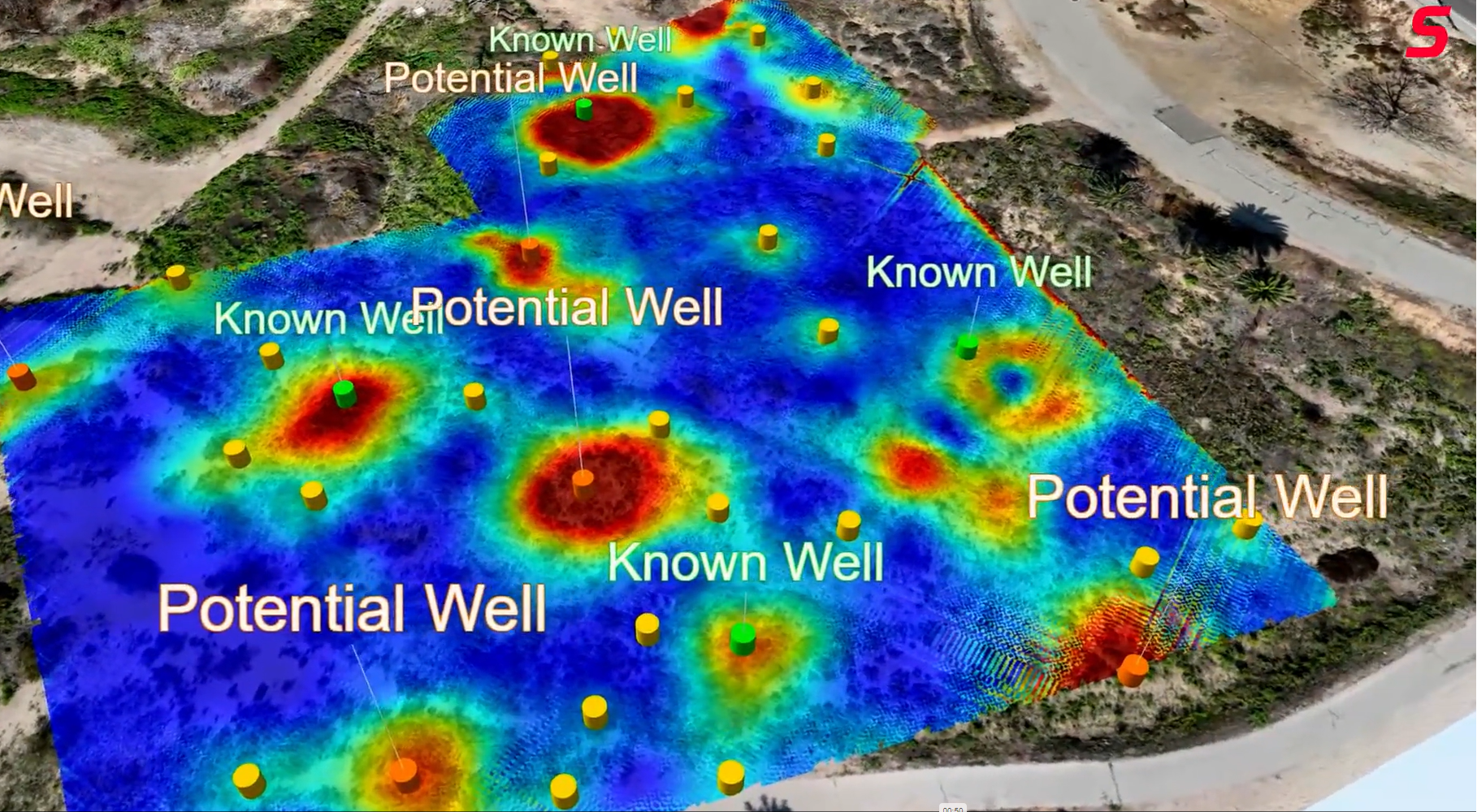

Data Post Processing & Exploration

After data collection, we calibrate for accuracy, filter and interpolate to enhance reliability. We then generate magnetic maps and analytic signals to provide comprehensive insights for informed decision-making.

Magnetic Inversion, Optimization Algorithms

Create georeferenced magnetic maps of the inspected area, detailed magnetic environment (magnetic noise, nearby metallic objects). Provide pre-inspection reports, including XY positions of wells.

Third Party Data Integration

Integrate third-party datasets and present them in a user-friendly interface for the client.

Assessment and Selection

Define critical bending strain limits, analyze spatial data for root cause diagnosis, and deliver a final inspection report with actionable recommendations.