Bending Strain Assessment

Geohazard events have the potential to impact buried infrastructure, triggering failures with catastrophic consequences. Rapidly and accurately assessing a pipeline mechanical condition following such an event is critical.

Key Challenges

Managing pipelines in areas prone to geohazards is a formidable challenge, exacerbated by several factors:

- High-Risk Locations: Pipelines intersect sensitive environmental zones, increasing the probability of severe consequences.

- Weather-Related Impacts: Changing weather patterns can affect buried pipeline environments.

- Measurement Limitations: Few tools are available to directly measure bending of underground pipelines.

- Inspection Difficulties: Many pipelines in geohazard areas cannot be easily inspected.

Cuting-Edge Solution

Skipper NDT offers a cutting-edge drone-based technology designed specifically for quantifying below-ground pipeline positions. Our solution addresses regulatory and operational integrity requirements with the following advantages:

- Field Operator Safety: Ensures safety with fully automated, remote data acquisition.

- Operational Flexibility: Adapted for metallic pipelines from 2” /5cm to 48”/120cm in diameter.

- Efficiency: Covers up to 1 mile/1,5 km per day, enhancing operational efficiency.

- Bending Strain Assessment: To identify bending strain locations due to ground movements.

- Proven Technology: Used by major operators - PG&E, Chevron, and Enbridge - and evaluated in a PRCI project.

Site Feasibility

Assess locations for current conditions: right-of-way status, precise positioning, vegetation coverage, access points, and accessibility to a Cathodic Protection system (CP).

Automatic Drone-Based Inspection

Next, we mark inspection area boundaries and map above-ground markers for thorough coverage. Drones follow precise trajectories, capturing detailed data.

Data post Processing & Exploration

After data collection, we calibrate for accuracy, filter and interpolate to enhance reliability. We then generate magnetic maps and analytic signals to provide comprehensive insights for informed decision-making.

Magnetic Inversion, Optimization Algorithms

Create georeferenced magnetic maps of buried pipelines, detail magnetic environment (parallel pipelines, nearby metallic objects). Provide pre-inspection reports, including XYZ mapping upon request.

Bending Strain Calculation

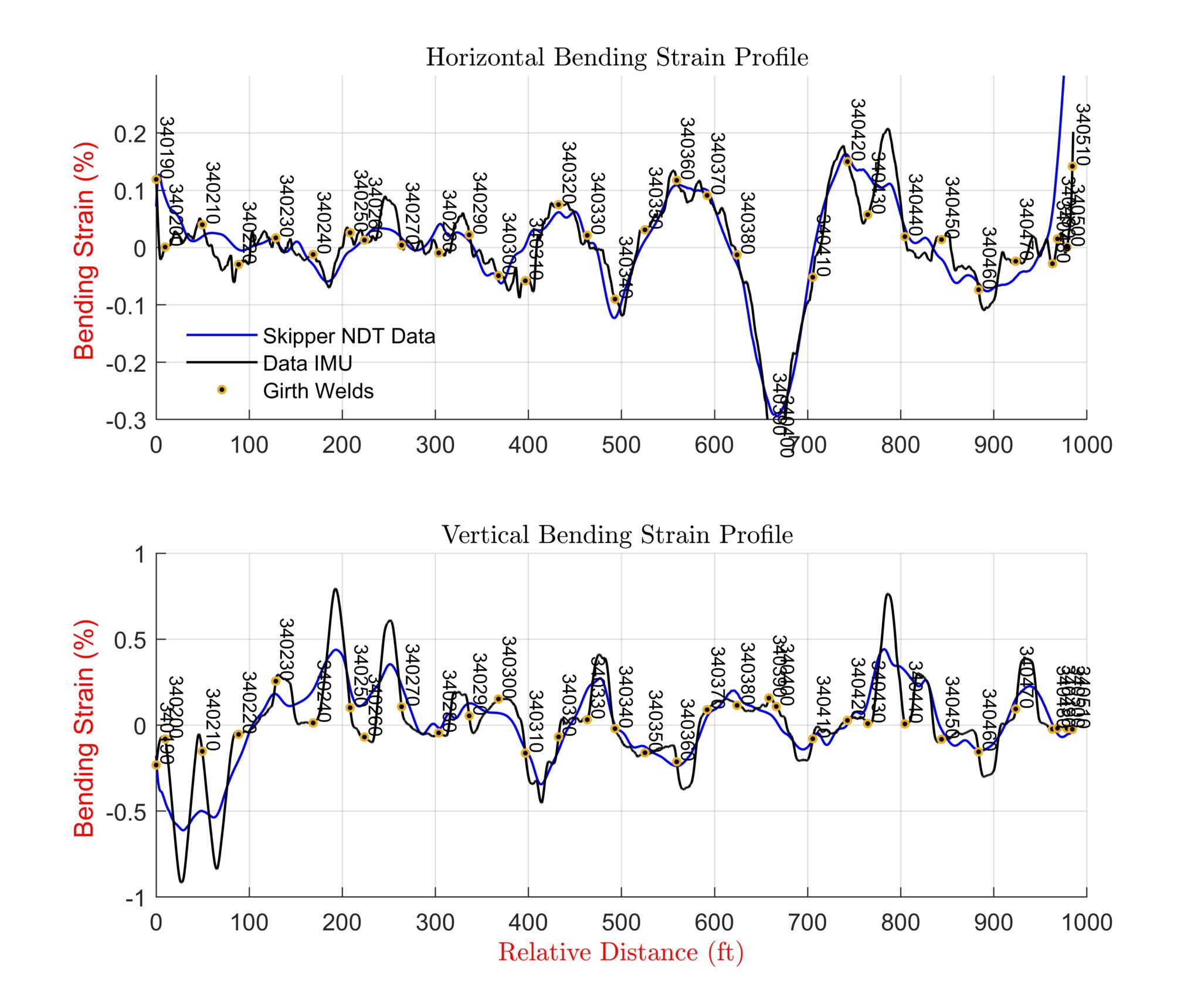

Provide plan/elevation views and horizontal/vertical out-of-straightness assessments. Offer pitch and azimuth profiles, along with vertical, horizontal, and resultant bending strain profiles for comprehensive analysis.

Assessment and Selection

Define critical bending strain limits, analyze spatial data for root cause diagnosis, and deliver a final inspection report with actionable recommendations.